Claudio Rolandi

ACADEMIA s.a.s., Italy

claudio.rolandi@academia-eng.com

Abstract

One of the results of the European “Smart Resilience” project was to provide a new methodology to assess and manage the resilience of critical infrastructures, i.e. their ability to cope with possible scenarios or adverse events that can potentially lead to significant disruptions in its availability.

Lean Thinking, on the other hand, is a management style that aims to reduce waste to create excellent, standardized and low-cost processes, making it adaptable to all sectors and contexts. Its application in the analysis of complex processes, such as the infrastructures, can be an effective optimization tool.

Starting from the considerations made on the prevention of risky events, some significant cases will be examined in order to increase the level of prevention, reduce recovery times and improve performance following the actions taken.

Keywords

Maintenance Management, Asset Management, Critical Infrastructures

Introduction

Every country defines which are critical infrastructures:

- For some countries, energy production, railway networks, electricity networks, aqueducts, highways, railway networks, ports, airports, armaments manufacturers, health system, …

- For other countries, sectors related to food, such as bread and milk, and health, such as vaccines and antibiotics, are also strategic, hence the financing and control over companies in the respective sectors.

For a critical infrastructure is important to be:

- strong enough to withstand unwanted and unpredictable events;

- fast enough to restore the situation prior to the event and also improve resistance as a result of the lessons learned.

Starting from the analysis of the vulnerability of critical infrastructures, using the Lean Thinking tools that have been successful in the Manufacturing sector, this document wants to suggest

improvement criteria for critical infrastructures to allow them to be ready to support unforeseen events and to be ready to recover quickly.

Critical Factors

In my work on failure prevention, I set out to use the ISHIKAWA 8M model for Root Cause Analysis and define what is out of control:

- Materials: both in acceptance and in production and in distribution or provision of services, according to the specifications;

- Machines: all technical devices available to carry out the required operations, including structures, mechanical, electrical, instrumental and software parts;

- Methods: ways of working adopted by the operations and maintenance departments;

- Manpower: personnel employed by the operations and maintenance departments, included technics, supervisors and engineers;

- Milieu (environment): depending on the external aspects in which one finds oneself operating

(climate, events such as earthquakes, floods, fires, legislation, socio-political aspects such as internal or external service strikes, reputation, etc.);

- Measurements: ability to keep quantitative and qualitative control parameters under control and make appropriate use of them;

- Management: ability and autonomy to make decisions;

- Money: necessary and available budget to the service department.

For me, all digitalization tools will have to allow these parameters to be governed, suggesting to those who have to decide the best solution with the least ethical and economic risks.

For each critical sector it is possible to define what could be the most relevant M-factors. A possible summary matrix could be the following.

The following table shows some sectors that could be considered critical. Each country, based on social, political, environmental or organizational culture considerations, can identify the most critical parameters to be monitored.

| Material | Machine | Method | Manpower | Milieu | Management | Measure | Money | |

| Transportation | ||||||||

| Energy | ||||||||

| Environment | ||||||||

| Healthcare | ||||||||

| Defence | ||||||||

| Life Sciences | ||||||||

| Food & Beverages | ||||||||

| Oil & Gas | ||||||||

| Heavy mechanics | ||||||||

| Light mechanics | ||||||||

| Primary and fine chemistry | ||||||||

| Paper mills | ||||||||

| Glassworks | ||||||||

| Metallurgy | ||||||||

| Semiconductors | ||||||||

| Optoelectronics components | ||||||||

| ICT | ||||||||

| Buildings | ||||||||

| Others |

Some notes:

- Artificial Intelligence is trained through Big Data.

- Large amounts of data are available on MACHINE.

- MATERIAL is often critical in upstream processes, as for foods & beverages, pharma & biotech, while is under control in downstream processes. The more regulated the industry, the fewer problems there are due to strict selection.

- Large influence of MILIEU and MANPOWER (also due to the presence of customers and outsiders to the service) is for sectors such as HEALTHCARE, ROAD and DEFENSE.

- ENERGY is strongly influenced by MILIEU and MONEY.

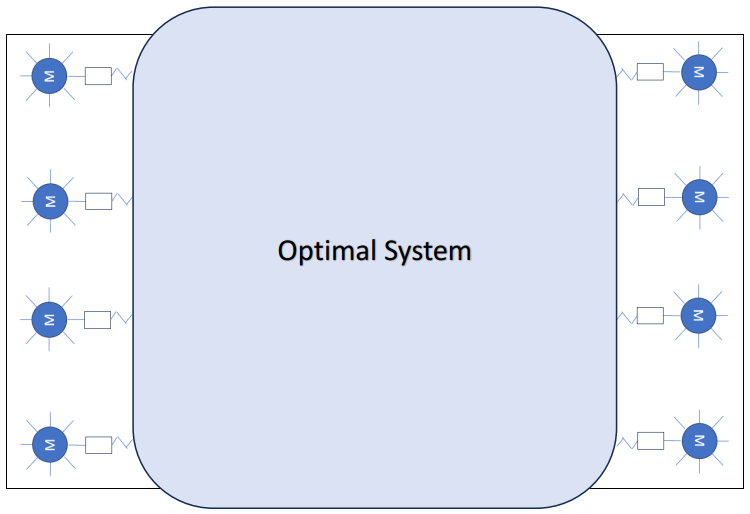

The system must take into account 8M constraints and consider from time to time what is the level of “stiffness” or “yielding” of each constraint.

It is therefore an optimization project of a complex system, in which some data are often not quantitatively well definable.

The failure of a “support” causes stress on the remaining ones:

- Money: e.g. lacks the necessary funding.

- Measure: e.g. feasible if convertible into electrical or optical signals, complex if biological indicators.

- Material: e.g. lack for environmental reasons, pollution, alteration.

- Machine: e.g. failure, unavailability, lack of spare parts, …

- Manpower: e.g. labour shortage, incompetence, conflict

- Method: e.g. inadequate or incomplete

- Management: e.g. incompetence and poor context vision

- Milieu: e.g. external events, predictable and unpredictable

When analyzing the context of an asset, especially if it is durable like a critical one, it is necessary to take into consideration not so much the Return on Investment or the Net Present Value as the Life

Cycle Cost and the Total Cost of Ownership, also estimating the risks due to unforeseen events and inconveniences.

Decisions are often made on the basis of containment of investment (CAPEX), which could be at the expense of operating costs (OPEX). Saving on investment could mean:

- lower reliability and availability of the plant;

- less skilled employees;

- fewer performing methods;

- greater conditioning by external events;

- lower quality raw materials and poorer final products;

- less precise instrumentation;

- less prepared management.

Resistance– Root Cause Analysis and Strengthening the Defenses (Prevention)

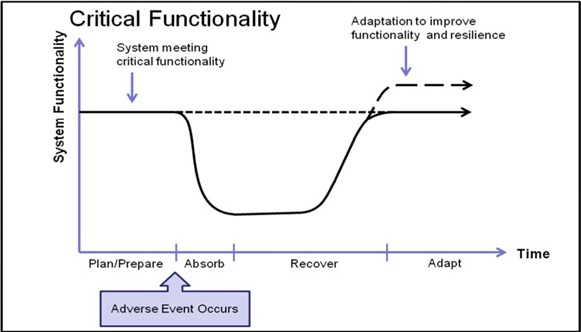

The typical representation of the functionality of the system is reported in the figure above.

Plan/Prepare phase.

If the adverse event is not a purely random adverse event, due for example to natural events, such as meteorological or earthquakes, or human events, such as vandalism or terrorism, scheduled,

condition-based and/or predictive maintenance are tools that can be adopted.

Absorb phase

Once an unwelcome event has occurred, it is necessary to ensure that the phase is not instantaneous and catastrophic, i.e. the slope in the diagram is too steep. It is possible to intervene both in the

planning phase (through passive and active protections) and by adopting organizational actions, such as organizing emergency response teams.

Recover phase

The phase represents the time to restore the pre-existing system conditions, possibly the same, sometimes degraded but preferably improved. Often the problems are not technical but legal, social or political. To reduce the time required, it is essential that the system design is easily repairable and upgradable.

Adapt phase

Based on the lessons learned, it is desirable to bring the system to a higher level of performance or increase its protections if similar unwanted events should occur.

An example of best practice

The Formula 1 driver hit the wall of the street circuit, damaging the front nose of the car. Slowing down for 15 seconds to reach the pits, in 5 seconds the damaged part was replaced, and in the

meantime the 4 tires, another 15 seconds were due to the passage to the pit lane. In total, the loss was 35 seconds on the performance on a lap of 1 minute and 50 seconds of pace. The opportunity to change worn tires with as many new ones allowed for an improvement in lap performance and

reliability.

Resilience – Lessons Learned, Restoring and Upgrading

Systems management is too often due to poor basic design, often dictated by an approximate analysis of the initial conditions, and a poor vision of what future developments could be.

Factors that are initially considered irrelevant can take on a preponderant value over time.

Many projects of the last century did not consider energy consumption, final

decommissioning, material recycling, CO2 emissions, the need for greater operator skills,

etc. would be relevant. Furthermore, mass production was favored at the expense of product customization, leading to systems with a defined expiry date. Now, however, preference is given to products and therefore systems that consume less energy during use, that can be

easily repaired or updated to extend their useful life and that can be easily recycled at the end of their useful life.

Case Studies

Airport of Catania and Mount Etna – Volcano Emissions

Mount Etna is also one of the most active volcanoes in the world, characterized by frequent eruptive activity from the summit vents and flank eruptions which an average of 4 events every 10 years.

There are no tools yet to predict volcanic eruptions.

The airport is located about 30 km away from the volcano and, if the wind comes from the north, the ash can reach the site within a few hours.

The main problem is due to ash on airport runways, taxiways, buildings and facilities. All this

involves the closure of the airport and the diversion to the other airports in Sicily, which are still poorly connected to each other by roads and railways.

Once the eruption has stopped, even after several days, removal can take several hours using appropriate means very similar to those used for removing desert sand from roads.

If it rains later, removal would be much more problematic and there would also be the problem of overloading the roofs of buildings and cleaning the infrastructures.

In this situation, the best solution remains to prepare means and teams capable of acting as quickly as possible to recover the minimum safety conditions for the reopening of the airport.

On the other hand, greater attention has been paid to the design of buildings and infrastructures to facilitate cleaning and restart operations.

Electrical panels in the Gotthard railway tunnel

The Gotthard railway tunnel consists of two tubes for the passage of trains. Every 325 meters there is a connecting passage between the two tubes, protected by fire doors, which serves as an emergency station in the event of an accident in one of the two tubes. Inside there are the ventilation, lighting and communication systems.

When they were first built, electrical panels were normally protected as if they were in an industrial environment.

Following frequent short circuits in the electrical cabins located in the emergency stations, it was discovered that they were full of dust. It was therefore decided to define an inspection and

intervention plan every two weeks to vacuum the dust, with related cancellations of freight trains during the night or diversions on the historic line. From the analysis, it was discovered that, when

trains passed inside the tunnel, at speeds of up to 230 km/h for passenger trains, it was found that the dust present on the external surfaces and that raised by the sediment was electrostatically attracted by the electrical cabins and settled inside.

As an improvement action, the electrical panels were modified to increase the level of protection from dust.

Preventive actions included requiring freight wagons to be appropriately covered with easily washable structures and prohibiting the passage of wagons carrying non-containerized bulk products.

Biotech manufacturing

In the case of extraction of active ingredients from natural substances, such as ginseng tuber, grape skin or ginkgo biloba leaves, the selection of the raw material, the extraction of the relative active ingredient, the selection of the compliant part with a significant influence on the yield, are relevant factors of the process.

Therefore, the upstream part is strongly influenced by factors such as Raw Materials, Methods and Measures.

In the subsequent downstream part, where it is a question of dosing, mixing, compressing or other

technologies, and packaging in controlled environments, the system is less subject to variability and everything is based on the compliance of the performances, dictated by:

- Operation and control of environmental conditions;

- Procedures by well-trained personnel;

- Operation of the machinery;

- Measurement and control of the process and the product;

- Traceability of the products;

- Reliability of machines.

Energy self-production and consumption

The introduction of incentives for self-production of energy through photovoltaic and wind systems led to an unexpected event last summer in some European countries: the negative cost of energy, due to the fact that the energy fed into the grid by these systems was greater than that immediately consumable and there were not enough storage systems.

In managing these assets, it is therefore necessary to rethink two different actions.

The first proposal is to change people’s habits. For years, domestic consumption during the night hours has been economically incentivized, to favor energy consumption by industries during day shifts.

The second proposal is to favor methods of storing excess energy, coming from systems that are highly subject to environmental conditions, directly on site where the energy is produced. In the case of domestic production, or by energy communities, a first step could be the use of various types of batteries

(electrochemical energy), although the costs and reliability of these systems are not yet optimized. Other possibilities could be the transformation into different storage systems, such as hydrogen production

(chemical energy) or in the form of potential energy (e.g. pumping water into elevated tanks or other gravity energy storage systems) or kinetic energy (e.g. flywheel energy storage).

All these new technologies imply a whole series of new implementations:

- high-performance and safe machines;

- support networks,

- professional skills;

- procedures;

- investments.

And last but not least, everything that could manifest itself as a result of the experiences that will have been gained.

References

- Smart Books – Cause & Effect Fishbone Diagram: Composition Notebook | Root Cause Analysis for Healthcare, Education, Business, Quality | Ishikawa Diagrams

- Smart Resilience Indicators for Smart Critical Infrastructures – Initial Framework for Resilience Assessment

- Ritsuo Shingo – My Leadership: The China Years

- Bunji Tozawa / Norman Bodek – The Idea Generator: Quick and Easy Kaizen